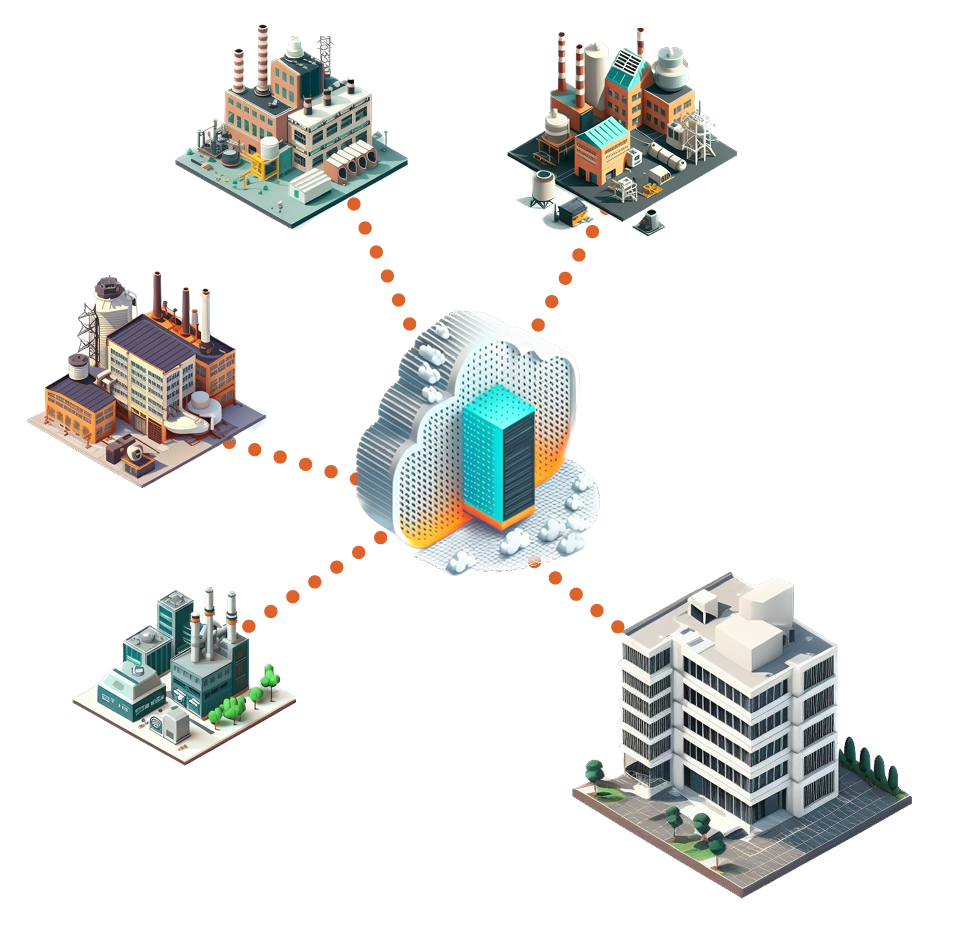

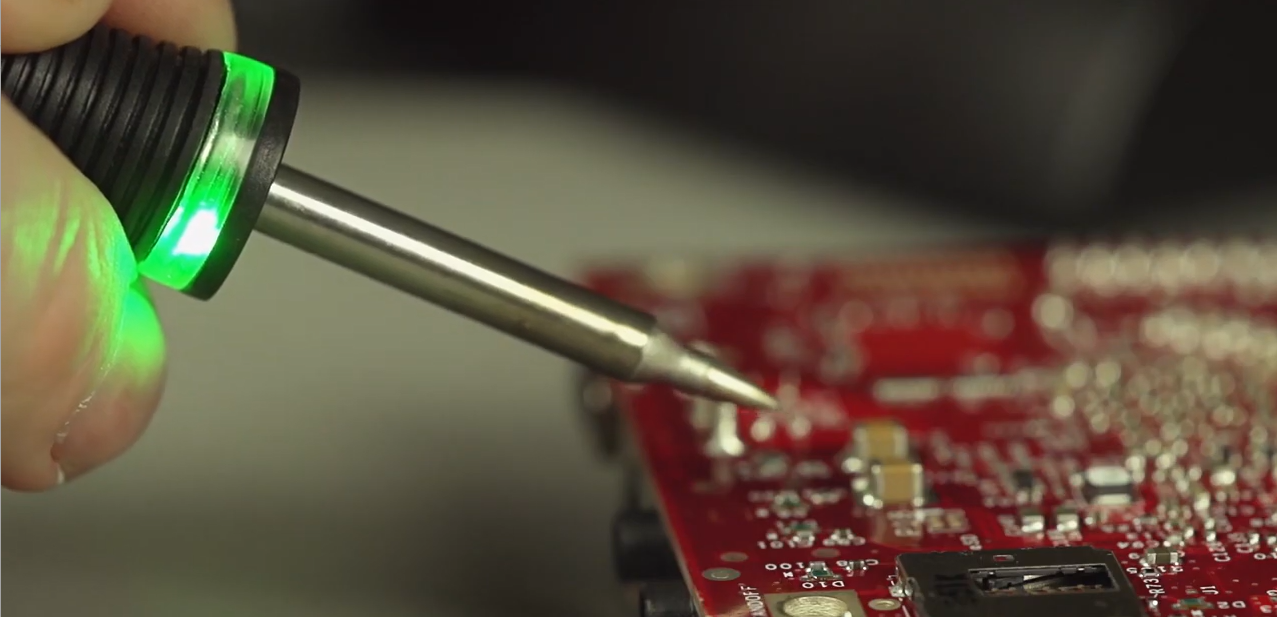

Track every joint being soldered. Not just locally, but from every site on your network.

Capture data at each soldering station on each joint – soldering temperature and power profiles, dwell time, good and bad solder joint evaluation, and more.

Analyze data through the intuitive dashboard and easy-to-configure software – easily view productivity and system status at-a-glance. Refine data views through filters and user configurations.

View data graphically or as a database – easily export data to a CSV file for your own analysis.

Add barcode information to your data set with a barcode scanner (not included)

The Ultimate in Process Control

- Identify which tips are being used at each station

- Track the soldering process through automatic evaluation of each joint, to ensure processes are being followed

- Understand productivity dips and spikes

- Set up email alerts for cartridge changes and ESD events

Advanced Traceability

- Review soldering statistics in the event of a board failure

- Find the root cause of faulty joints faster by analyzing data never before available

- Analyze valuable metrics on the processes at the bench. Drill down to the board level

The Advantages of CV-IOT

Information on the entire shop floor – At a glance, see how many stations are up and running, and how many are experiencing ESD events

Productivity Station-to-Station – Compare station productivity to easily manage throughput and see when operators may need extra training.

Tip Life – Manage costs and productivity by comparing expected and actual tip life at each system.

Explore the CV-IOT Gateway Software

The soldering station information screen allows the floor manager to see detailed information on the setup and productivity of each station.

Leverage graphs with multiple filters to customize dashboard displays, making it easy to have the information you need at your fingertips.

System Requirements

SOLDERING SYSTEMS: CV IoT Module and software are compatible with CV-500 and CV-5200 soldering systems. Upgrading to the latest version of the CV firmware for your system is always recommended.

COMPUTER HARDWARE: CV IoT software requires Windows 10, Intel® Core™ i5 or better, 2 GB of RAM, Intel® HD Graphics, at least 150 GB of storage, and Ethernet 10/100.

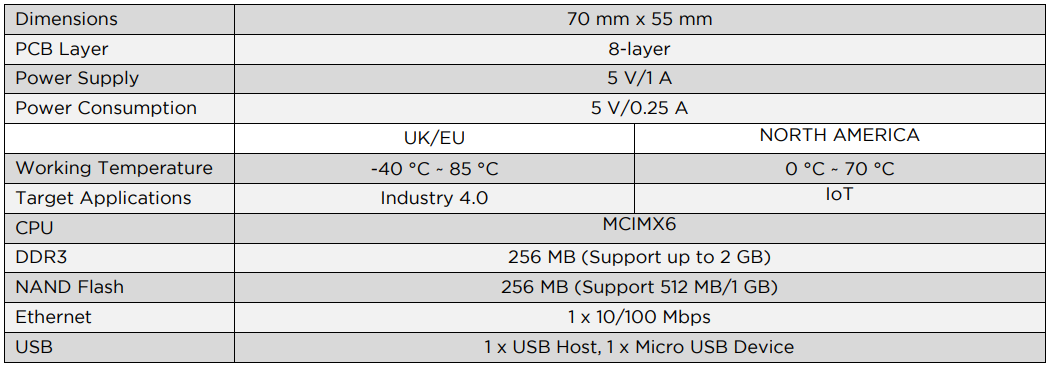

Technical Information

SOLDERING SYSTEMS

CV-IOT Module and software are compatible with all Connection Validation (CV) soldering systems. Upgrading to the latest version of the CV firmware for your system is always recommended.

COMPUTER HARDWARE

- Windows 10

- Intel® Core™ i5 or better

- 2 GB of RAM

- Intel® HD Graphics

- At least 150 GB of storage

- Ethernet 10/100.

- CVI-IOT Gateway

- Charger, 5 V, 500mA

- Software Instruction Guide

- Cable, USB 2.0 A Male to Male

- Cable, USB 2.0 A Splitter

- Cable, USB 2.0 A to Micro USB Male

CV-IOT: The module

CV-5210-IOT: CV-5210 Soldering System + CV-IOT module